Home / Hydrogen Generator

Hydrogen generators can use two very different technologies to turn hydrogen into electricity.

The first is the internal combustion engine – similar to the combustion engine used in current diesel generators. Here, a hydrogen-air mixture is burned inside a combustion chamber. Just like diesel, this miniature explosion produces force to turn a crankshaft and an electrical current is generated via the attached alternator.

The second technology uses a fuel cell (FC) to generate electricity. A fuel cell generates electricity by chemically reacting hydrogen with oxygen (usually from the air) to create water. Hydrogen is put into close contact with oxygen inside the fuel cell, separated only by a membrane – typically a proton-exchange membrane (PEM). The hydrogen’s proton moves through this membrane to react with the oxygen, which forces the hydrogen’s electron along a circuit to rejoin, creating an electric current. Water is then evacuated from the fuel cell as the only by-product. There are many different types of FC. However, in principle, they all work like this.

In most cases, a hydrogen generator will be connected to externally bottled hydrogen. This hydrogen is typically produced somewhere else and brought in gas bottles to the location of the hydrogen generator. Internally hydrogen generators will contain a FC, power electronics, control systems for electronics and gas, and often a battery to manage power up and down procedures as well as supply extra power during peak loads. Electrolysis is our system….

Always greener than diesel: Even when using Grey H2, hydrogen generators create just a third of the CO2 of a diesel generator. When using Green H2 it is carbon guilt-free.

Silent and no vibrations: No moving parts mean that hydrogen generators run virtually silent with no vibrations. Perfect for operating in urban environments or late into the night.

Zero emissions, Zero fuel spills: Hydrogen generators produce only water. No emissions or fuel spill risks make it ideal for Ultra Low Emissions Zones or environmentally sensitive locations.

Operationally equivalent: Mobile, plug-and-play deployment, and with similar operational procedures, it should lead to minimal operational or training changes.

Reliable and low maintenance: No moving parts reduce maintenance costs and increase reliability compared with diesel gensets. Thus, reducing project delivery risk.

Instant start and no need to idle: Sub-second response time, plus excellent start-up and load following. Also, hydrogen generators only consume H2 when power is being drawn. No idling means no waste. With our deployment experience, we have visited many sites which have had the diesel generator running but ultimately doing nothing (or simply powering some low-power equipment such as lights and security cameras). The waste comes from the fact that when diesel generators are at low load (when idling), the generator is in fact at its least efficient.

Whilst diesel generator idle waste can be solved by coupling it with a battery, most hydrogen generators already have built-in batteries. Plus, hydrogen generators are much faster to turn on if it is really needed to switch them off, which is not the case with diesel generators.

Below are some use cases where hydrogen generators can be used for optimal net-zero and performance benefits.

Datacenters,

Hospitals and Clinics,

Operation of Emergency Power,

TV/Film Production,

Remote Locations with Power,

Gas Stations, Commercial Buildings,

Hotels, Telecommunication Tower Sites,

Camp Sites , Farms, Backup, Off Grid

Designed for hydrogen fuel cell power systems with widespread component interoperability.

• H2O Generators will provides one-source responsibility for the generating system and accessories.

• Low-maintenance operation and reduced through-life costs.

• Flexible and scalable to suit a broad range of applications.

• Provides zero-emission power to decarbonizes customers energy needs.

Proven technology

The solution features a Solid Polymer Electrolyte Membrane (PEM) fuel cell for high-efficiency energy conversion.

Built to last

Compact, durable steel housing featuring lockable access doors and a textured paint finish for corrosion and abrasion protection.

Flexible operations

It can operate in a range of temperatures, from -30 to 45C, and has a low-maintenance 20-year design life.

Easy to use

Fully integrated controls, including externally mounted emergency stop switch, electronic trip main line circuit breaker and remote start/stop.

Meets stringent standards

Can be configured to meet the National Fire Protection Association’s NFPA110 standard for emergency and standby power systems.

Single-source solution

The hydrogen fuel cell power system is prototype-tested and factory-built within Utilitarget H2 AquaBurn facilities.

Multi-purpose applications

Can be used for prime power, peak shaving and emergency power with the option to export excess energy to the grid through a net metering program.

Supports net-zero ambitions

When hydrogen comes from a renewable source such as solar, the system produces zero emissions across its lifecycle, offering a sustainable solution.

This chart shows by 2030 the production of H2O will be at its peak. Many other companies are seeking this type of energy production and it is just a matter of time before it reaches the USA. Europe is already ahead of the game and since 2004 has been switching over to H2O operations for most of their businesses and housing. Our goal is to bring the USA up to date on this technology.

Based on the customers needs the unit size is dependant on the amount of energy used by the customer and the type of system the customer is looking to have the unit perform: Off Grid, Back up system, Demand Reduction to reduce the high cost of energy used at peak Utility operation hours.

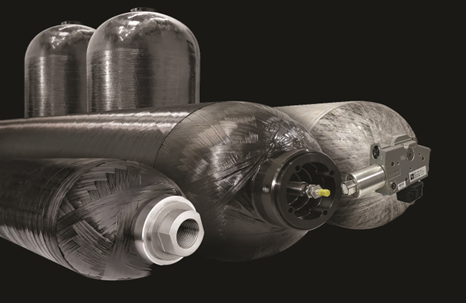

The photos on the side show that the system can be grown from a level 1 to level 3 size.

Each size has its limitations and conditions to be met for the production of H2O.

You still need energy from somewhere to produce the H2O. Some options are the following:

Energy for the production of H2O still has to come from somewhere?

As mention before the power to produce the H2O has to come from somewhere?

The photo on the side shows this power being used as a night time charging system to produce the H2O during off peak hours to cut the amount of energy the customers uses during the daytime when their peak demand charges are over $12kW. The unit would operate during the daytime along use with the utility companies power and off of the H2 AquaBurn System ,removing their high demand charges by inserting power into the facility to off the peak usage.

The most popular system would be to use the free energy produced by the sun to ether go OFF GRID or Reduce the Demand operating cost from the electric side of the grid. This system would only charge during the daytime, however, it all depends on the customers usage and size of the system. The system can store enough energy to just have the day- time solar system charge the system during the day as well as still being able to supply electric energy to facility. Every- thing depends on what the customer is looking for.

A small 8.6kW solar system could cost the customer an extra $14k and the customer would get 2 rebates back.

25% from state $ 30% back from government. So almost half of the system could be paid for from the rebates.

Another part of this system would be the grid tie that would also use the solar and the utility company, to charge the sys- tem with both scenarios, free sun and utility companies power. So when cloudy days are not charging the system the night time power can come from utility company.

Each system will have several tanks that are certified for H2O storage. The tanks can be sourced here in the USA, Colorado. This would help keep shipping costs down and meet the USA H2O storage standards. Every system would be using the tanks for the storage of the H2O production.

Systems are based on the amount of H2O storage the system can hold.

Our tanks are coded YELLOW, GREEN for Electrolysis H2O This chart shows the amount of H2O a tank can hold.

Outside

Diameter

(mm)

435

435

435

435

Outside

Diameter

(in)

17.12

17.12

17.12

17.12

Length

(mm)

1016

1422

2110

2616

Length

(in)

40

56

83

103

Water

Volume

(L)

90

133

205

270

Hydrogen

Capacity

(kg)

2.07

3.0

4.85

6.2

So why switch over to H2O?

Simply put, the future is going that way now.

We can generate H2O from Blue Energy, which is natural Gas production of the gas and ship H2O to the customer to have their H2 AquaBurn System filled up.

We can use Electrolysis to produce Brown Gas-On Demand at the customers site to produce H2O. This way the customer is in control of his own production of H2O.

Both work very good, Our systems have a capability to grow in size. Everything is designed on the production and storage of H2O in the certified storage tanks.

It takes 50kW of energy generation to make 5kW of power. This is the storage rate of the system. So a 8.6kW solar system producing 40Kw of generation will only make enough charge gas for 5kW. This is only x16 panels of 410W solar.

Users have the possibility of an energy storage credit through the federal government. This is a provision that is available through 2025.

Clean Hydrogen Production Credit

This is a 10-year incentive for the production of energy using fuel cells. This gives users up to $3 per kilogram or a 30% investment tax credit.

Hydrogen fuel cells are eligible for a 30% federal tax credit using form 3468

| Kg of CO2 per kg of H2 | Credit Value in Dollars |

| 4 – 2.5 kg CO2 | $0.60 / kg of H2 |

| 2.5 – 1.5 kg CO2 | $0.75 / kg of H2 |

| 1.5 – 0.45 kg CO2 | $1.00 / kg of H2 |

| 0.45 – 0 kg CO2 | $3.00 / kg of H2 |

How much space do I need for the system?

Most applications will only take up about a 4×4 ft. area. This space should be located near the “load box”. The installation team will help you locate this area and develop a strategy for placement.

Can I store the system indoors and outdoors?

Yes. The system can be stored indoors, in a garage or outdoors adjacent to a building.

Is this ESG compliant?

Our process helps your company come into compliance with increasing Environmental, Social, and Governance (ESG) standards adopted by business leaders and government entities around the nation. Hydrogen fuel cell technology is one of the best and most optimal ways to help you actually achieve ESG compliance in the future.

Is this system 100% green, clean & safe?

Hydrogen fuel cells are a form of green, carbon-free, sustainable energy.

What is a MicroGrid and how does it work?

More and more people are becoming concerned with the reliability and the availability of power. When there is an outage, planned or unplanned, and there is no power; what can we do? The solution to this problem is MicroGrids.

Key benefits of the MicroGrid……

H2 AquaBurn is a solutions provider of systems that are fully optimized to be a scalable hydrogen fuel cell system. These systems can turn hydrogen made with renewable energy into sustainable power – with no compromise on performance.

The modular and scalable Hydrogen fuel cell system allows mission-critical power users to rapidly deploy a sustainable energy solution that produces zero emissions at the point of use. Depending on the application, the system can be used as a prime or backup power source or as part of a distributed energy network.

Full systems integration with touch-screen control.H2 AquaBurn is responsible for customization and systems integration of the fuel cell power system, with a large color graphical AQUAPM802 controller continuously monitoring and managing operating conditions to ensure reliable and flexible performance.

Call to discuss about your project (716) 871-1111

A Carbon Neutral Go Green Provider.

Copyright © 2024 H2 AquaBurn All Rights Reserved.